At a Glance

- A Filipino copper mining tycoon aimed to reduce its production costs and enhance efficiency, particularly as it planned to expand its processing plant.

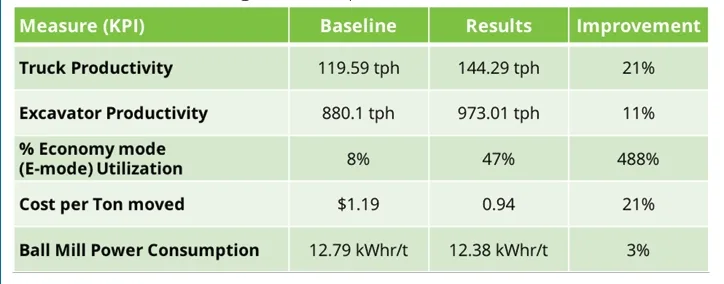

- The partnership resulted in a notable 21% reduction in mine cost per tonne moved, a significant achievement.

- This case study looks at how Renoir’s know-how led to driving performance improvements and reducing operational costs.

Key Results

- 304% improvement in goods receipts (GR) compliance

- 134% improvement in crusher planned maintenance

- 118% improvement in PR to PO conversion within 7 days

- 39% improvement in mill planned maintenance

- 24% improvement in goods issues (GI) compliance

- 21% reduction in mine cost per ton moved

- 21% improvement in dump truck productivity

- 12% improvement in drill availability

- 11% improvement in excavator productivity

Background

Metallic mineral exploration and mining are complex, capital-intensive processes in which operational efficiency is critical. Inefficiencies, whether due to declining ore grades, poor planning, labour shortages or inadequate maintenance, can cause operational costs to escalate, jeopardising the profitability and sustainability of mining ventures. The mining industry in the Philippines faces substantial capital requirements and high operating costs, particularly regarding electricity expenses, compared to global standards. Infrastructure bottlenecks, such as an unreliable electricity supply and high logistics costs, further increase operational expenses.

The client operates one of the Philippines’ largest copper mines through a wholly owned subsidiary. The mine is a key contributor to the country’s copper exports. With over a thousand employees and expanding beneficiation operations, the client sought ways to improve efficiency, reduce operational costs, and increase the commercial viability of by-products such as molybdenum, magnetite, and pyrite.

Analysis

Renoir was appointed to assist the client’s subsidiary in substantially reducing its operational costs. The overarching goal was to optimise operations, especially in conjunction with the expansion of the beneficiation plant. The initial assessment identified a minimum opportunity of $ 5.16 million in annualised savings.

The client was facing challenges that necessitated improvements in several key areas to achieve these cost reductions:

- Enhancing planning and productivity within mining and milling operations.

- Improving maintenance planning, productivity, reliability, and reviewing current spare parts and procurement practices.

- Optimising the organisation structure to support these operational efficiencies.

Project Approach

Renoir structured the project into three major workstreams:

- Mine & Mill Operations

- Maintenance & Procurement

- Organisational Design

A Management Action Team (MAT) was established for each workstream, led by relevant senior leaders to ensure alignment and ownership. Renoir’s proprietary Focus Process® methodology was used to develop solutions for each workstream.

“Renoir’s strong commitment and remarkable abilities have helped [the client’s subsidiary] attain improved operational performance, and their continued involvement will ensure the sustainability of these achievements.”

– President and CEO.

Implementation

Renoir and the client co-developed and implemented new Management Control Systems (MCS) across all workstreams.

Key initiatives included:

Mine & Mill Operations

- Designed a Line Balancing Forecast Model for better production planning

- Revamped operational workflows to enhance mine readiness

- Established KPIs with visual dashboards and review mechanisms

- Clarified roles and responsibilities through a RACI chart

- Introduced behavioural audits to monitor performance

Maintenance & Procurement

- Standardised maintenance processes and introduced structured planning tools

- Deployed supply chain tools and job standards, including inspection checklists and root cause analysis frameworks

- Implemented performance dashboards and SLA tracking

- Rolled out an MCS for maintenance and supply chain operations

Organisational Design

- Conducted KPI mapping for all relevant departments

- Completed performance appraisal validations for operational staff

- Developed an Organisational Design Manual to guide future workforce planning

“The introduction of the design system element from Renoir significantly improved the maintenance approach. The overall effect has been an increase in productivity.”

-Mill Maintenance Division Head

Results

After the implementation phase is complete, the results will be measured against KPIs.

Both mine and mill operations have successfully achieved the key objectives:

- The project’s key success measures have been implemented, as have improved management and control systems.

- The control system (MCS) has helped mine operations increase truck

- and excavator productivity, as well as increasing the utilisation of E-mode and decreasing

- The power consumption of the milling operation has decreased.

*Client-specific details have been intentionally omitted to maintain strict discretion.

Ready to reduce your operating costs and maximise productivity?