At a Glance

After a 5-month project with Renoir, and the implementation of an updated Management Control System in its Maintenance Execution, Planning and Materials Procurement Departments, the client saw the following results:

- 75% reduction of maintenance work order backlogs from 5361 to 1298

- Increase in workforce productivity from 18% to 50%

- 63% Increase in YoY completed maintenance jobs

- Clear departmental KPIs and work processes

- Increased materials availability and stock accuracy

Background

The client is an LNG plant in the Western Pacific. With almost 800 working personnel and a facility over 130 hectares, the plant focuses on large scale liquefaction and transportation of natural gas which commands a sales volume of over 6 million tonnes of LNG annually. It has established itself as a major revenue earner in the region and is expected to have a plant life until the year 2070.

The Challenge

Renoir was approached to conduct an improvement project to revise working practises and increase productivity and performance of its Maintenance Execution (EME) department. Emphasis was placed on sustainably changing behaviours of EME personnel to enable productivity improvement and at the same time, implement a reduction program on the ever-increasing EME work order backlog.

The focus was to design, develop and install changes in the following:

- Maintenance planning and work order backlogs

- Maintenance execution supervisory routines & Execution Information Systems

- Materials management practices

What We Did

The project kicked off with Renoir’s Focus Process® and Implementation, developed over many years and based on experiences with hundreds of successful assignments. The process took the client’s staff through a learning experience that promoted commitment and ownership of the solutions being implemented, whilst retaining the company’s essential organisational goals and corporate identity.

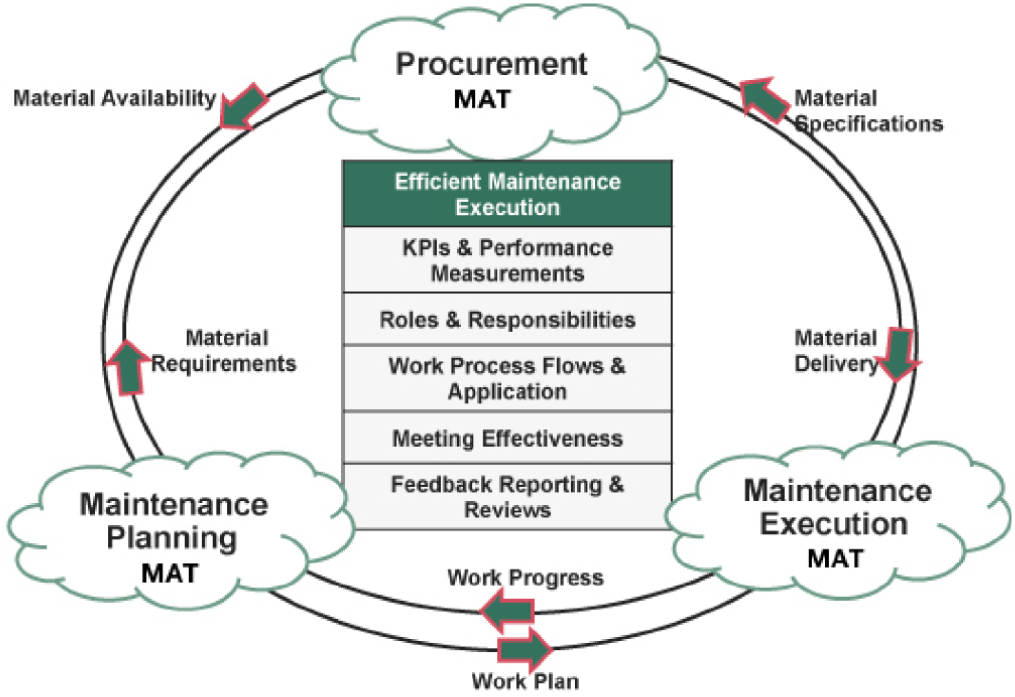

To achieve maximum impact and employee buy-in, “Management Action Teams” (MATs) were set up, led by the client’s Business Improvement, Maintenance Planning, Maintenance Execution and Material Procurement managers to directly engage the EME team in implementing the required Improvements.

Management system drives efficiency and contractor compliance

Utilities company reduces rework and churn with updated MCS

Management system drives efficiency and contractor compliance

Utilities company reduces rework and churn with updated MCS

The Results

Renoir, together with the client’s MATs, were able to design, develop and install improved Management Control Systems (MCS) and work processes in Maintenance Planning, Execution and Materials Procurement.

The MCS and work processes provided complete information loops from the start to completion of maintenance execution jobs, empowering managers to take effective management actions and monitor departmental performance.

The project provided the respective client departments with key performance indicators that are applicable not just at the ground level but also reported to the client’s board of directors. Clear work processes, roles & responsibilities and performance reviews were also established for Planners, Supervisors and Technicians, enabling the identification of improvement areas and the appraisal of high performing individuals.

EME workforce productivity, a mere 18% at project start, increased to an average of 52%, five months after project implementation. This enabled EME to achieve a 63% increase in job completion compared with the previous year. The client’s Total Maintenance Backlog was also significantly reduced from a high of 5361 down to 1298.

The Project has also resulted in the advancement of the plant as a whole. Its Maintenance Execution compliance to GAS-GAME, an assets management audit, showed a preliminary increase from 44% to 72%. Additionally, the EME department’s ability to improve the timely execution of maintenance jobs ultimately contributed to the improvement of plant integrity.

In conclusion, the MCS is now an integral unit of the client’s EME department, and has enabled and empowered the Planning, Maintenance Execution and Procurement Teams to take actions to improve the performance of their respective departments.

“We are in a totally different place from 6 months ago and I can now effectively manage the performance of my department.”

Engineering Business Support Manager

Empower managers with clear work scopes and responsibilities.