At a Glance

- A prominent Middle Eastern food and beverage company was struggling with inefficiencies in operations, sales management, and reliable data visibility.

- Renoir partnered with the client to introduce robust Management Control Systems (MCS), strengthen sales routines, and streamline operations across divisions.

- As a result of this collaboration, expired product returns fell from 3.14% to 2.18%, unlocking an annualised benefit of US$839K. This case study explores how Renoir’s approach delivered sustainable improvements and measurable business impact.

Key results

Expired returns cut from 3.14% to 2.18% (US$839K annualised value)

Production up 10% to 4.4M litres (US$1M annualised value)

Dairy plant downtime reduced by 31%

Improved sales levers: customers, order size, frequency (US$213K annualised value)

Saleable meat yield up 3% (US$415K annualised value)

Chick cost down 3.6% (US$694K annualised value)

+1,500 MT sales pipeline (US$984K annualised value)

Lease and fuel savings (US$380K annualised value)

Background

The client is a diversified food and beverage company based in the Middle East, employing thousands of staff across multiple divisions. Established in the early 1980s, it has grown into one of the country’s leading dairy producers, operating the largest single-site dairy farm in the region. Its portfolio includes dairy products, fresh juices, oils, and feed, with a strong market presence across the Gulf and Africa.

In the food and beverage industry, “expiry returns” occur when products are sent back by distributors or retailers because they are unsellable due to reaching, or nearing, their expiry date. These returns not only create direct financial losses but also add operational inefficiencies in handling and disposal. They are often a symptom of weak demand forecasting, sales planning, or distribution processes. On this case study, the client approached Renoir to address the challenge of high expiry returns, which stood at 3.14%.

Analysis

The client sought a structured approach to address inefficiencies across operations and sales.

Key Findings included: .

| Challenge Area | Key Findings |

| Organisation & People | Misaligned structures; need for future-focused design, competency framework, and skills matrix |

| Finance & Governance | Weak credit policy exposing business to non-paying customers; lack of dashboards for accounts receivable oversight |

| Sales & Customer | No daily routines or feedback loops; underdeveloped sales culture; limited training and tools for active selling |

| Operations & Efficiency | Weak operational metrics; absence of equipment loss accounting; inconsistent supervisory routines |

| Farm Management | Gaps in processes requiring best-practice checklists and structured cleaning schedules |

Ready for a change in your organisation?

Project Approach

This multiple-week phase involved thoroughly examining management control systems, business processes, performance levels, and supervisory and managerial issues.

Renoir designed a transformation programme built on Management Control Systems to address the client’s pain points. The approach included:

- Mapping the existing organisation and redesigning future structures, competencies, and skill frameworks.

- Strengthening cash management through new policies and enhanced accounts receivable monitoring.

- Establishing operational excellence frameworks in poultry, dairy, and feed divisions.

- Designing daily sales routines and modules to instil a proactive sales culture.

- Creating dashboards and KPIs to track performance at both divisional and group levels.

- Renoir formed a joint taskforce with the client’s PMO, supported by Management Action Teams (MATs) for each workstream, and a Steering Committee of directors for oversight.

Implementation

The transformation was executed over 44 weeks across eight workstreams. Key initiatives included:

- Introducing dashboards for daily and weekly performance monitoring.

- Installing a Loss Accounting system with real-time data to identify and address production losses.

- Reducing logistics costs through renegotiated leases, fuel optimisation, and faster speed-to-market, adding 1,500 MT to the sales pipeline and $82K in monthly contribution margin

- Embedding a RACI matrix for clear accountability and improved communication across departments.

- Establishing product-to-route processes for sales to align supply chain decisions with real-time market needs.

- Training employees in supervisory skills, loss accounting, and root cause analysis, ensuring sustainability through knowledge transfer.

Results

The project delivered measurable improvements across both operational efficiency and commercial performance.

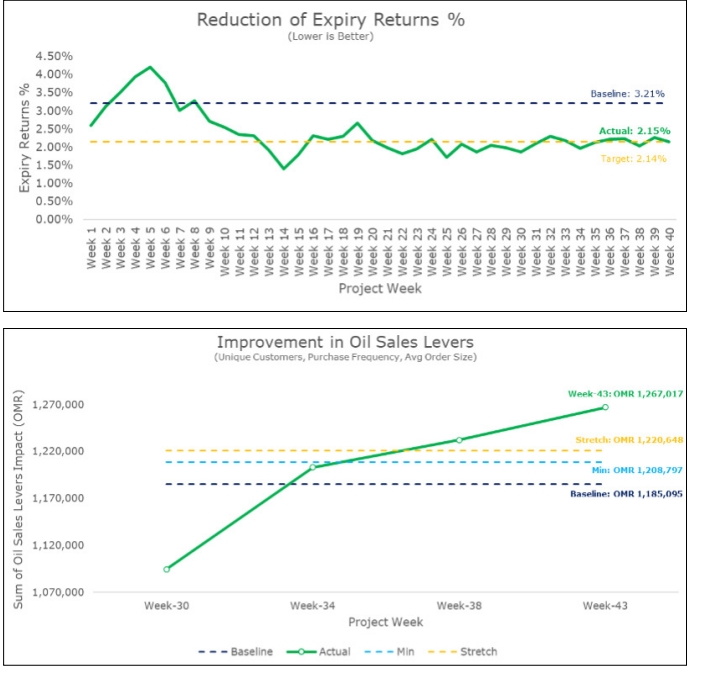

Expiry Returns: Expired product returns fell significantly, from a baseline of 3.21% to 2.15% by Week 40. This improvement outperformed expectations and translated into substantial cost savings.

Oil Sales Levers: By focusing on key sales drivers such as customer acquisition, purchase frequency, and average order size, sales impact increased from a baseline of OMR 1,185,095 to OMR 1,267,017 by Week 43. This result exceeded the stretch target and unlocked new revenue opportunities.

These results demonstrate how Renoir’s structured methodology and Management Control Systems enabled the client to achieve both operational cost reductions and stronger top-line growth.

*We have intentionally omitted client-specific details to maintain strict confidentiality.

Does your organisation need operational transformation to deliver sales growth and cost savings?